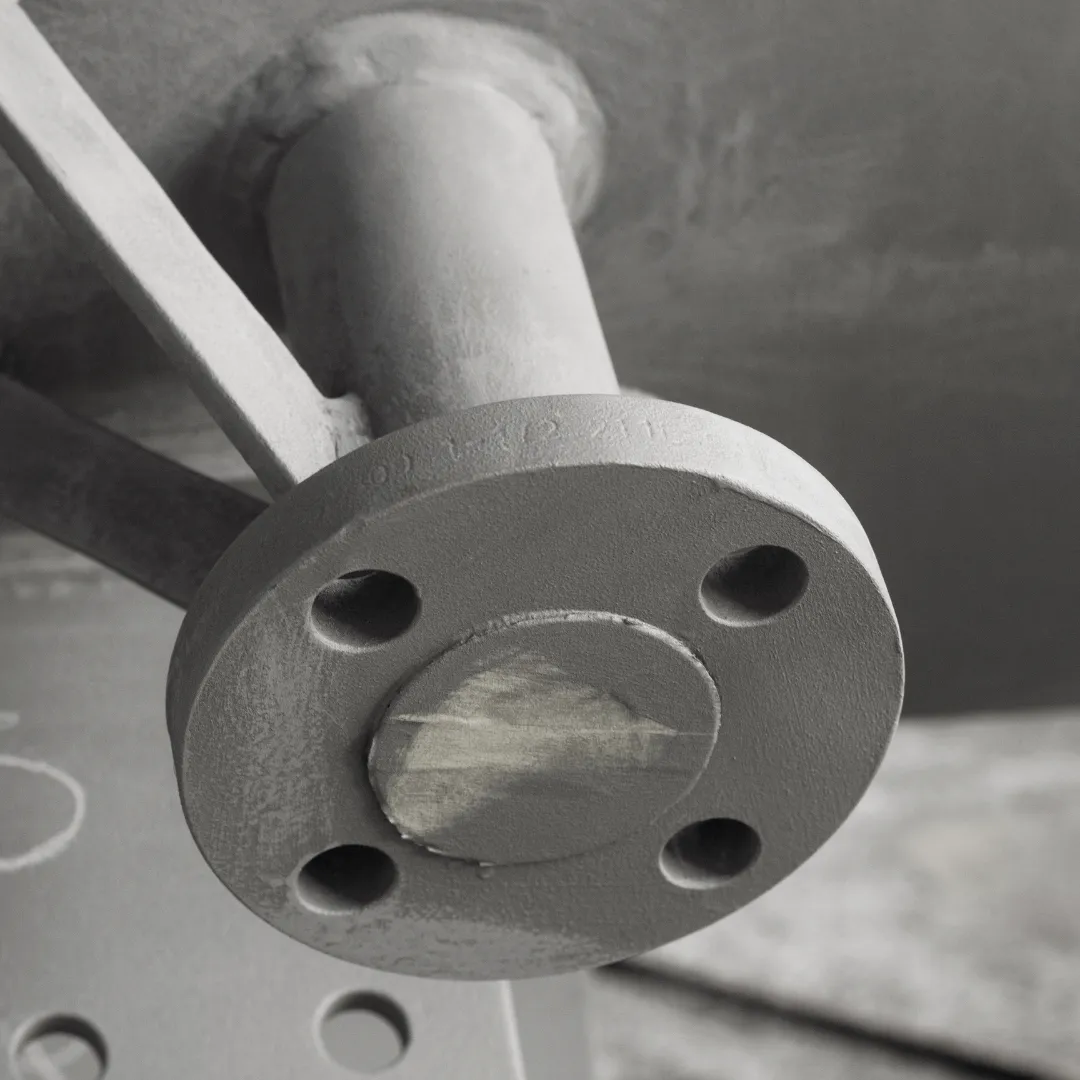

Mac Mechanical is a specialist provider of highly skilled prefabrication and pipework engineers offering a high-quality service in mild steel off-site prefabrication, including spool designs, fabrication and coded welding.

Mac Mechanical is a specialist provider of highly skilled prefabrication and pipework engineers offering a high-quality service in mild steel off-site prefabrication, including spool designs, fabrication and coded welding.

PREFABRICATION & PIPEWORKS EXPERTS

Lee McFadyen CEO, established Mac Mechanical in 2006. Having worked in the heating and ventilation sector since the early 1990’s, Lee offers a vast knowledge of the industry and a wealth of experience in the installation of specialist industrial pipework.

To date we have delivered projects to a wide range of applications and buildings that include:

DATACENTRES

HOSPITALS

COMMERCIAL

WATER TREATMENT

INDUSTRIAL FACILITIES

LEASURE FACILITIES

GOVERNMENT

SPECIALIST SERVICES

- Pre-insulated Pipes

We offer a broad range of service pipe and casing solutions – to ensure that we can meet the requirements of any application or media. Our bonded pre-insulated pipe systems provide outstanding performance and reliability across a wide range of temperatures and pressures.

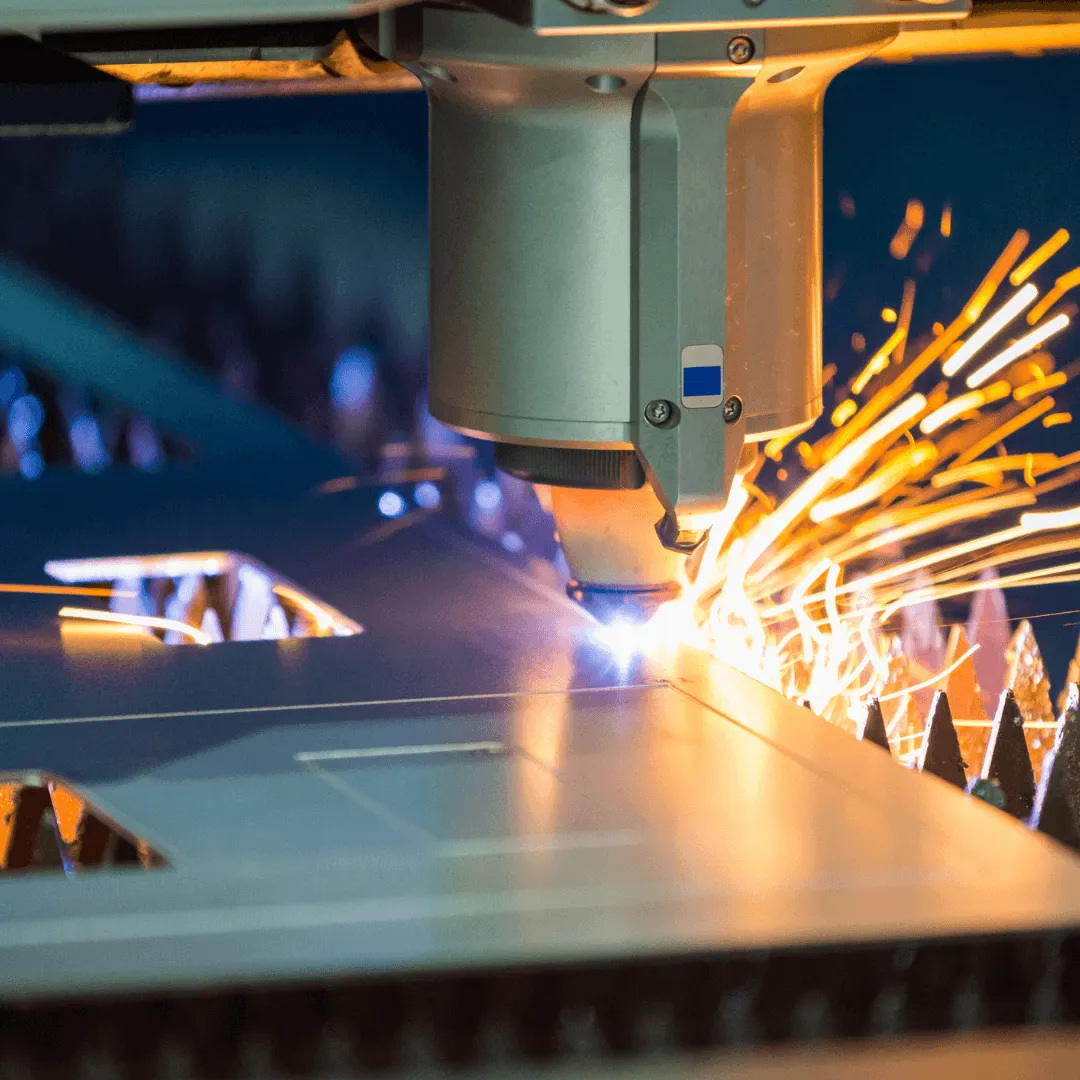

- Mechanical Fabrication Services

Our off-site fabrication services are available to mechanical building services (single wall and dual-contained), irrespective of their materials or purposes, including, but is not limited to: Heating, Chilled water, Drinkable water, Hot water, Gases and Compressed air

- Vestibules and chambers

Upon request, we can manufacture a variety of chambers and vestibules using a wide range of polymer materials. Additionally, we can include all valves, fittings, and other relevant equipment to provide complete solutions ready for installation.

- Hazardous and process drainage

We offer above- and below-ground chemical and hazardous drainage systems and dual-contained/pipe-in-pipe solutions for various applications, including laboratories in schools, universities, hospitals, and medical, pharmaceutical, chemical, petrochemical, and biotechnology research facilities.

- Storage tanks

We have a lengthy history of producing polymer storage tanks in a variety of materials. We can also incorporate all valves, fittings, and other relevant equipment to provide complete solutions ready to be installed on-site.

- Customised solutions

While the list above is exhaustive, we are adaptable enough to tailor our products to any potential application. Kindly contact us to discuss your specifications.

Customised Solutions

We are adaptable enough to tailor our products to any potential application. Kindly contact us to discuss your specifications. Experts in a wide variety of materials we maintain an extensive inventory of heavyweight and standard weight pipe fittings enable us to maintain a high level of agility, allowing us to complete projects on schedule and within budget.

We're able to start new projects quickly upon receipt of order and without delay due to our extensive range of fittings and pipework, which includes:

MILD STEEL

STAINLESS STEELS

ALL CARBON STEELS

GALVANISED

PAINTED

Quality Assurance

Mac Mechanical enjoys an exceptional reputation for service and quality. We are devoted to consistently delivering a high-quality product and service on schedule and accomplished by adhering and conforming to a stringent Quality Assurance process.

Each project is weld mapped to ensure complete business control and traceability of all fabrication data. Depending on the deliverables, a certain amount of Non-Destructive Testing (NDT) is included in each project. NDT enables the tracking of specific welders assigned to each weld and identifies which welds have or have not undergone NDT.

Our shop and office workers thoroughly analyse each component of each job performed by our experienced workforce, and we hold monthly meetings to assess and debate ways to enhance our work policies. As a result, our rules and practices have been proven effective, and our track record holds up to any chosen metric or review.

All of our welders have been tested to ASME 1X, EU187, Class 1 BS2633, and Class 2 BS2973, which are all well-established standards that are easily available for examination.

HEALTH & SAFETY

Mac Mechanical as a company adheres to stringent health and safety policies, which has resulted in zero human fatalities and zero environmental issues over the last 15 years. We regularly review and update our policy to ensure that it complies with current regulations and the overall legal and moral obligations of the Health and Safety at Work Act 1974, a copy of which is readily accessible for your review upon request. This has aided us in creating an environment that rewards effort and achievement.

At Mac Mechanical, the safety of our employees, clients, and community is critical to every aspect of our work. We adhere to best practices in health and safety at all times, regardless of the size or scope of the project. Furthermore, we will always incorporate any client-specific protocols when required.

INDUSTRY CERTIFICATIONS

At Mac Mechanical, we ensure that all operators are thoroughly qualified and competent in all facets of the work. Training records are maintained to guarantee that any training that is about to expire is renewed in a timely manner so that we can ensure all our operatives are fully compliant.

CONTACT US

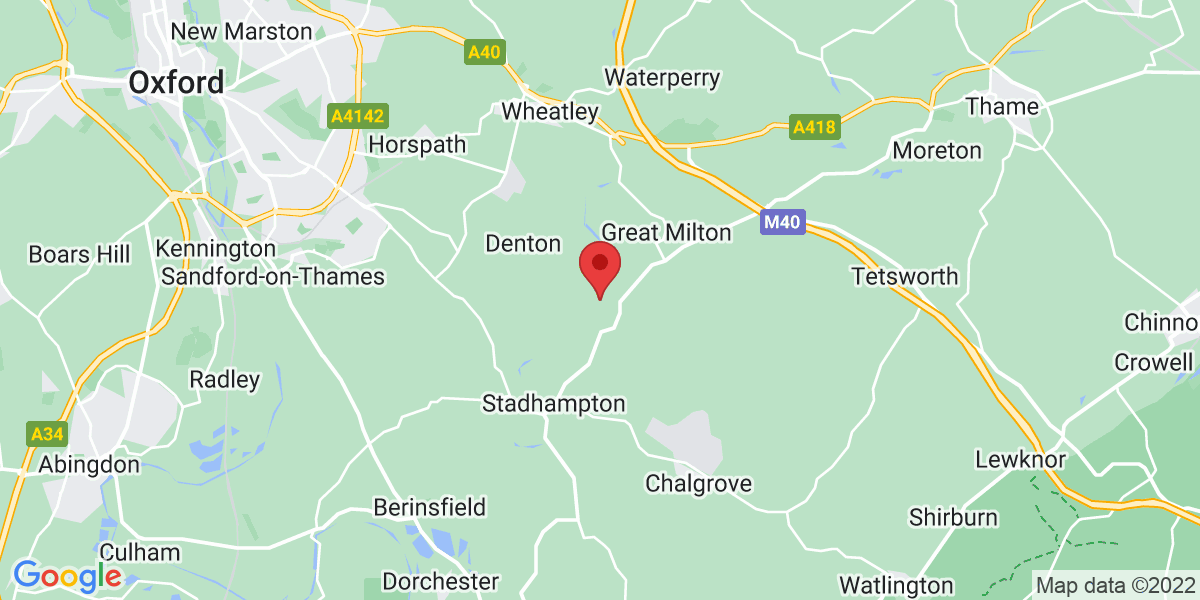

- Unit 10, Warren Barn Farm, Little Milton, Oxfordshire, OX44 7PR, UK

Leading the way in the supply of specialist industrial pipework contractors.

3210

Miles of Pipeline laid

500

Projects Completed

94

Happy Customers

about Mac Mechanical

We always strive for growth and development. We don't want to have a large team, we want to have a team that works in unity. Our slogan is "Every day is the last day." - Lee McFadyen CEO

Contact

- Unit 10, Warren Barn Farm, Little Milton, Oxfordshire, OX44 7PR

MAC MECHANICAL LTD is a company registered in England and Wales with the company number: 05824487 whose registered office address is Unit 10 Warren Barn Farm, Little Milton, Oxfordshire, England, OX44 7PR.